- Industries

Industries

- Functions

Functions

- Insights

Insights

- Careers

Careers

- About Us

- Technology

- By Omega Team

A few years ago, the world became aware of 3D printing technology. In 3D printing, the object stays stationary while the printing tool moves on three axes to construct an object. With the help of the computerized CAD model, the object is created.

3D printing is now used in the manufacturing industry for making components. Simple and complicated components can be manufactured. In the automobile industry, 3D printing is commonly used for creating metal, rubber, and plastic objects. It is also used in creating homes by using the concrete mixture as a material.

In recent years, the innovation of 4D printing has become a new milestone. The use of 4D printing is greater in the healthcare industry due to the use of many related applications.

What is 5D Printing?

5D printing is a new branch of additive manufacturing. In this technology, the print head and the printable object each have five degrees of freedom. Instead of a flat layer, it produces curved layers. The print portion revolves while the printer head is printing in this operation. As a result, rather than proceeding through a straight layer like 3D printers, printing follows the curved path of the component being printed. The main advantage of this technology is that it creates parts with a curved layer with improved strength.

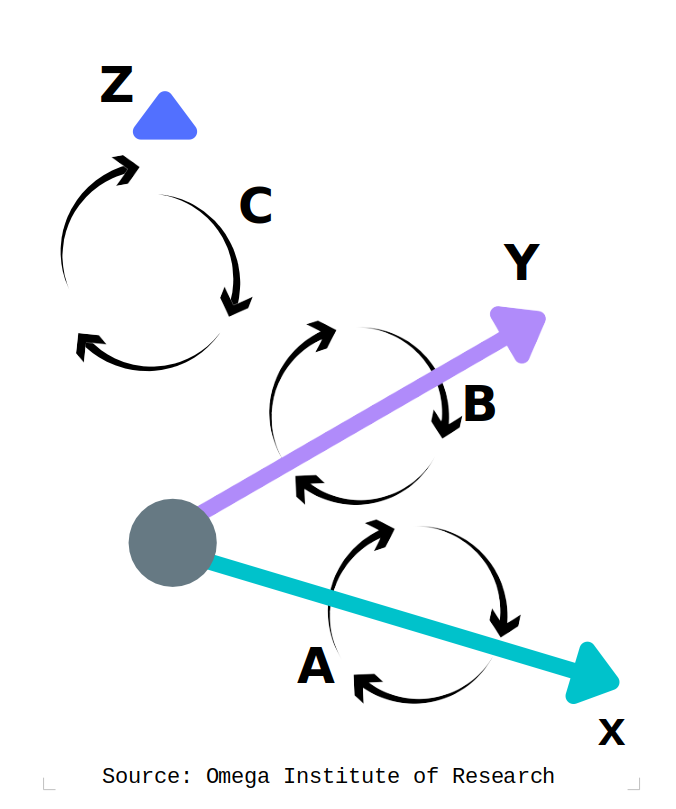

The name “5D printing” comes from the five axes used for creating objects. In this printing, the printing head can move in x, y & z-direction(axis) and the printing bed is capable of moving in 2 directions (axis). The print head and the printing bed can move simultaneously while printing.

First Implementation

The concept of 5D printing was first implemented by the Mitsubishi Electric Research Lab(MERL). William Yerazunis (Senior Principal Research Scientist) explained that, in 5D printing, the object is built with the help of 5 different axes that will help in creating a complicated object with good strength.

According to Mr. Yerazunis, the goal is to make parts that are strong in the directions they need to be strong in, no matter what those happen to be. If we build a pressure cap with a conventional 3D printing technique, the cap layers all lie flat, and the force of the pressure inside will easily rip the tank cap apart along the line of adhesion between the layers.

What we consider is that the force will come from within and change the layers from flat to curved along the lines of maximum stress in the pressure cap. We can make that part 3 to 5 times stronger and use 25% less material to do it.

Unlike standard 3D printers, which only use the X-, Y-, and Z-axes, 5-axis printers use 2 more:

- A: Rotation in the X-axis.

- B: Rotation in the Y-axis.

6-axis printers, which take advantage of the “C-axis” – rotation in the Z-axis – also exist. Like 4-axis printers, though, these are fairly rare.

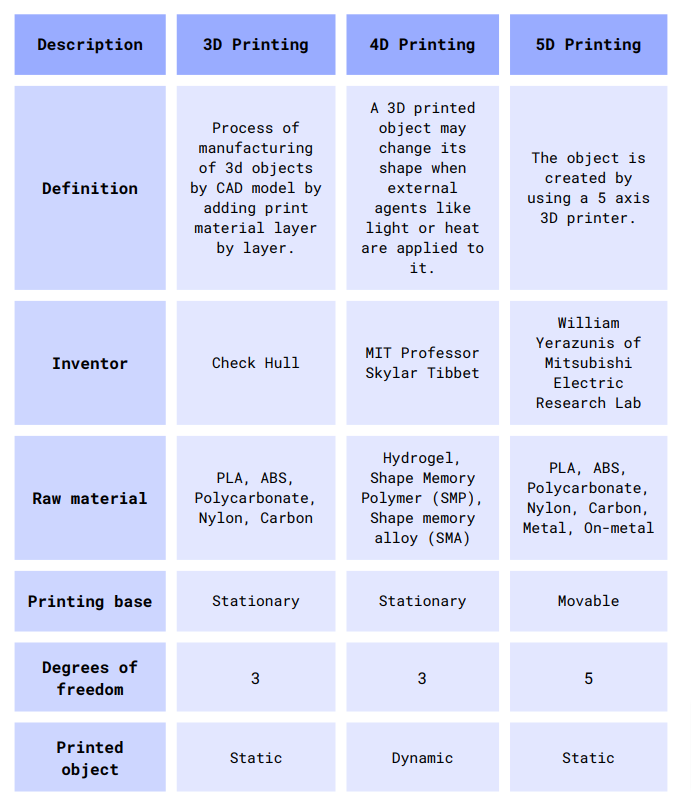

Difference between 3D,4D and 5D

printingThe key differences between 3D, 4D, and 5D printing technologies are as below:

Applications

Dentistry: With the help of 5D printing, some of the surgical equipment like dentures, dental implants, and other devices that are complicated in shape are manufactured. Also, teeth that have curved shapes and curved parts are made accurately with the required surface finish and reliability. The strength needed for the equipment is higher and it can be done with this technology only.

Orthopedic Surgery: For the manufacturing of human body parts, it requires exact accuracy and good strength. Because these parts are used inside your body, it is necessary to have the proper shape and size. This technology is useful for manufacturing artificial bones with excellent strength because curved parts are manufactured with good accuracy and require a surface finish. Other objects that are complicated in shape are not able to be manufactured with 3D printing—they can be manufactured with 5D printing.

Prosthetics: For making artificial body parts, the use of 5D printing technology is common. In today’s time, when someone loses a leg, hand, fingers, jaw, or other parts of the body in an accident, prosthetics are used in their place.

As we know, these kinds of parts require more strength. These artificial body parts are frequently used for their respective applications. So much strength is acquired by this 5D printer technology.

Manufacturing Surgical Equipment: Manufacturing surgical equipment is a delicate business. We do require high cutting accuracy, sharp edges for cutting, good strength to bear the force applied and proper shapes. This technology fulfills these kinds of requirements.

Good ergonomics and aesthetics of the equipment help the surgeon grip it in a proper manner. It improves accuracy and reduces the chances of accidents. By using this technology, the manufacturing of monopolar diathermy, DeBakey forceps, mosquito forceps, and Deaver retractors is possible.

Construction & Automobile components: The strength required for the construction & automobile component is higher as compared to the other component. So, it is necessary to have good strength. So, 5D printing is useful in the manufacturing of houses with curved designs and complex parts.

Case Study

In orthopedic surgery, it is an essential requirement for complex and strong implants to have curved surfaces. Five dimensional printing prints these complex surgical implants as per the actual surgery of the patient and is also applicable in surgical planning, teaching, and learning. So, 5D printing can easily create a sophisticated and curved structure that requires a lot of strength.

In orthopedics, these smart materials can be well-utilized for the manufacturing of implants for complex surgical cases by taking data from computer tomography (CT) and magnetic resonance imaging (MRI) scanning techniques. This data can easily be modified to 3D CAD file format using different softwares like 3D slicer, Mimics, OsiriX Imaging Software, Magics, 3D doctor an InVesalius for use in 5D printing.

The nature of 5D printing is a combination of subtractive and additive techniques. According to MERL, 5D printing does require quite some analysis beforehand on how the 5D printed parts will be used. So, the best way 5D printing can be implemented is for complex structures and designs that require a lot of strength.

Halo 5D Printer

The Bengaluru based company, Ethereal Machines, which used to sell 3D machines, came to learn about the 5D printing technique. They spent more than a year developing the concept, and the company thought of making a machine that combines additive and subtractive printing techniques.

This is Ethereal Machine’s Halo 5D printer, which won the Best of Innovation CES 2018 award. The design allows them a lot of added flexibility when making 3D printed objects on a typical 3D printer. The head moves from layer to layer, depositing a thin amount of extruded plastic, essentially breaking down the object into flat slices and printing them out.Advantages over 3D Printer

Fewer supports: Thanks to being able to rotate the printhead or bed in the A- and B-axes, you can ensure the printer is almost always printing on a solid part of the model, eliminating the need for excessive supports, and enabling more intricate and complex models to be printed, where supports would have otherwise been impossible to remove.

Stronger Prints: Standard 3D prints are always the weakest across their layer lines. With 5-axis printing, you’re not limited to stacking flat layers in the same way and so can produce much stronger prints. 5D printed parts are 5x stronger as compared to 3D & 4D printed objects.

Less Material Used: Being able to print at a variety of angles reduces the need for infill and supports, so the amount of material used can be dramatically reduced.

Less post-processing: By not needing so many supports and not being limited to flat layers, it’s possible to produce much smoother, higher-quality prints with less need for postprocessing. Additional advantages include a curved layer object with great strength, use for creating complex prototypes in the medical field as well as in the automobile, 5D printing objects having a higher life span, fabrication of a complex object with 25% less material.

Disadvantages over 3D Printer

A few options: The market for 5D printing is kind of partially untapped. It is often intended for industrial use or is pretty expensive, making 5-axis printing fairly inaccessible for most.

Limited support: There’s also very limited support available for these printers compared with something like standard 3D printing, where there are huge communities of users.

Complex slicing: Creating and slicing models for 5-axis printing can be difficult. 5-axis printing requires a very different approach, so you’ll likely have some habits to break when it comes to designing or selecting models to print. Furthermore, most slicers don’t even support non-planar (true 3D) printing, never mind 5-axis printing! In other words, if you want to slice a model to be printed using a 5-axis machine, you will have very limited and mostly paid options, along with a steep learning curve.

Future Approach of the Printing Industry

The three key branches of additive manufacturing are 3D, 4D, and 5D printing. Leveraging these printing technologies allows very high levels of precision in manufacturing to be achievable. The tailored implementation of printing techniques for specific purposes enables the fabrication of sophisticated, high-strength components. We can expect further breakthroughs in the printing enterprise ahead. Technological innovations will aid in the faster, more reliable, and more efficient production of components.

Conclusion

5D printing fulfills the drawbacks of 3D and 4D printing. It has got high strength and is able to make curved and complex parts. Researchers are investigating this technology to increase its capacity to withstand pressure up to 3.4 MPa.

So that it is useful in high pressure applications in the medical and manufacturing industries. It reduces 20 to 30% of wastage. Due to its various advantages, this technology will be widely used in all sub-sectors of medicine in the future.

Subscribe

Select topics and stay current with our latest insights

- Functions