- Industries

Industries

- Functions

Functions

- Insights

Insights

- Careers

Careers

- About Us

- Healthcare

- By Omega Team

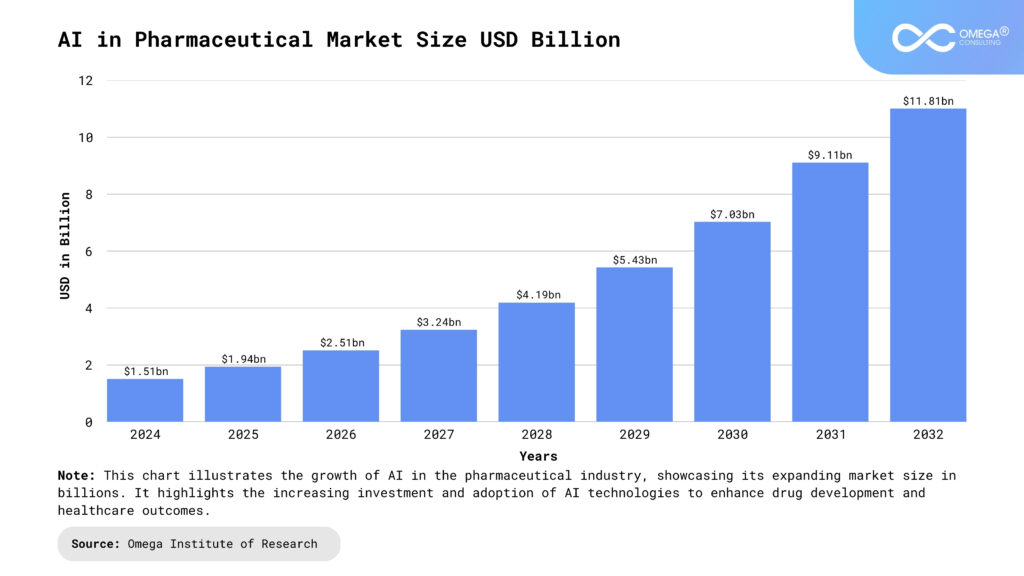

The pharmaceutical industry operates within a complex and highly regulated environment, requiring seamless coordination across global supply chains to ensure patient safety, compliance, and efficiency. Traditional supply chain models often face inefficiencies, delays, and vulnerabilities, but Artificial Intelligence (AI) is transforming the landscape by enhancing decision-making, improving forecasting, optimizing logistics, and increasing resilience. By leveraging AI-driven solutions, pharmaceutical companies can streamline operations, reduce risks, and respond more effectively to demand fluctuations. This article explores how AI is revolutionizing the pharmaceutical supply chain, the key benefits it offers, and the challenges organizations must overcome to fully harness its potential.

The Role of AI in Pharmaceutical Supply Chains

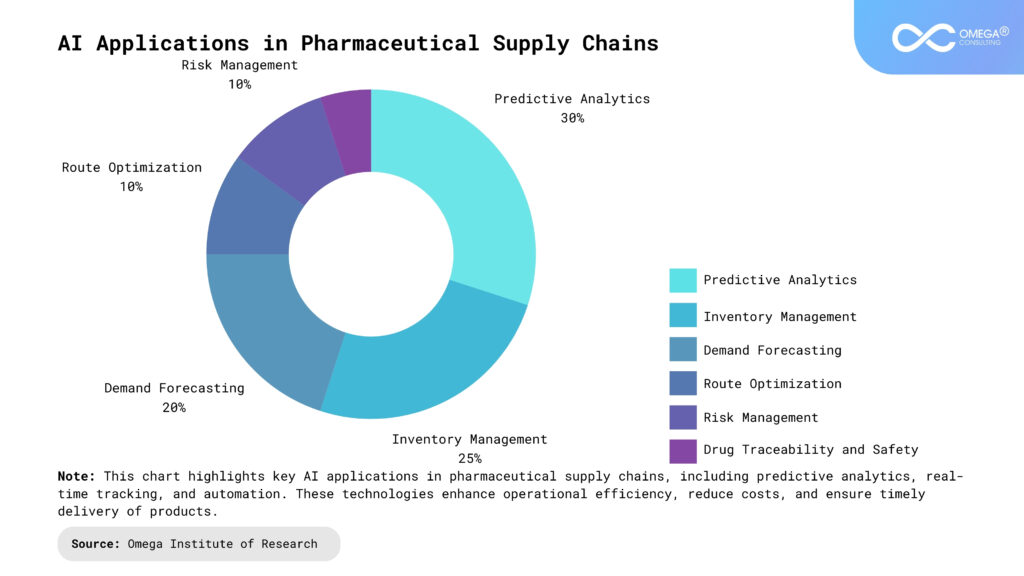

Demand Forecasting and Inventory Optimization: AI-powered predictive analytics help pharmaceutical companies forecast demand with remarkable accuracy. By analyzing historical sales data, market trends, and external factors (such as seasonal changes and pandemics), AI algorithms can predict demand fluctuations, reducing instances of overstocking and stockouts. This ensures that critical drugs remain available to patients while minimizing waste and storage costs.

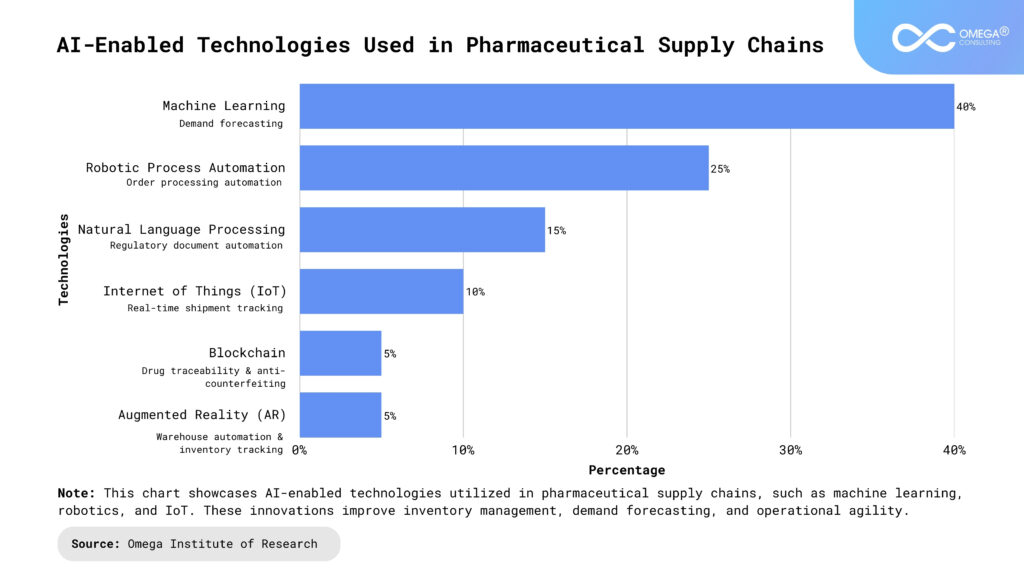

Supply Chain Visibility and Transparency: AI-driven supply chain management platforms provide end-to-end visibility, enabling pharmaceutical companies to track raw materials, active pharmaceutical ingredients (APIs), and finished products in real time. Blockchain-integrated AI solutions further enhance transparency by recording every transaction securely, helping to prevent fraud, counterfeiting, and regulatory non-compliance.

Cold Chain Management and Logistics Optimization: Temperature-sensitive drugs, such as vaccines and biologics, require precise storage and transportation conditions. AI-powered IoT (Internet of Things) sensors monitor temperature, humidity, and transit conditions in real time. Machine learning models analyze this data to predict potential failures and recommend proactive interventions, reducing the risk of product spoilage.

Risk Management and Resilience Planning: Supply chain disruptions—such as raw material shortages, geopolitical conflicts, and natural disasters—can significantly impact pharmaceutical production. AI enhances risk management by analyzing global supply chain networks and identifying vulnerabilities before they cause disruptions. Machine learning models suggest alternative suppliers and distribution routes, ensuring continuous production and delivery.

Automated Drug Manufacturing and Quality Control: AI-powered robotic process automation (RPA) and computer vision technologies streamline drug manufacturing by automating quality control checks. These systems detect defects, inconsistencies, or contamination in real time, reducing the reliance on manual inspections and improving compliance with stringent pharmaceutical regulations.

Regulatory Compliance and Documentation Automation: Pharmaceutical companies operate in a highly regulated environment with strict compliance requirements. AI-driven natural language processing (NLP) automates regulatory documentation, reducing human errors and ensuring adherence to Good Manufacturing Practices (GMP). AI also helps companies stay updated with evolving global regulations, minimizing the risk of non-compliance penalties.

Counterfeit Drug Detection and Prevention: The global counterfeit drug market poses serious risks to patient safety. AI-powered image recognition and blockchain solutions verify the authenticity of pharmaceutical products at every stage of the supply chain. Advanced algorithms analyze packaging, serial numbers, and distribution data to detect and eliminate counterfeit drugs from circulation.

Benefits of AI in the Pharmaceutical Supply Chain

Enhanced Efficiency and Cost Reduction: AI-driven automation streamlines supply chain operations, reducing manual intervention, errors, and operational costs. Machine learning algorithms optimize production schedules and inventory management, minimizing inefficiencies. Predictive analytics help prevent stockouts and overproduction, leading to significant cost savings.

Improved Patient Safety: With better forecasting, real-time tracking, and counterfeit detection, AI ensures that safe and effective medications reach patients without delays or risks. AI-powered quality control systems identify defects and deviations in drug manufacturing processes. Advanced analytics help detect adverse events early, enhancing pharmacovigilance.

Greater Agility and Resilience: AI enables pharmaceutical companies to quickly adapt to disruptions, ensuring continuous supply and mitigating potential shortages. Predictive models assess risks such as geopolitical events or supply chain bottlenecks, allowing proactive mitigation. AI-powered demand sensing enables faster responses to market fluctuations and emergency situations.

Sustainability and Waste Reduction: AI optimizes inventory management, reducing drug wastage and promoting eco-friendly supply chain practices. Smart logistics systems reduce carbon footprints by optimizing transportation routes and minimizing energy consumption. AI-driven demand forecasting prevents excess production, decreasing expired and discarded pharmaceuticals.

Regulatory Compliance and Risk Mitigation: Automated compliance checks and documentation reduce the risk of regulatory violations, protecting companies from financial and reputational damage. AI assists in maintaining accurate and updated records for audits, ensuring adherence to global regulations. Natural language processing (NLP) tools analyze regulatory updates, helping companies stay compliant with evolving standards.

Key Challenges in AI Adoption for Pharma Supply Chains

AI adoption in pharmaceutical supply chains faces hurdles like high costs, complex integration with legacy systems, and ongoing maintenance expenses. A shortage of in-house AI expertise increases reliance on costly external vendors. Regulatory compliance and fragmented data further complicate implementation, requiring transparent AI models and high-quality data.

High Implementation Costs: AI solutions often require significant investment in technology, infrastructure, and skilled personnel. For many pharmaceutical companies, particularly smaller players, the cost of AI implementation can be a major barrier. Beyond the initial setup, ongoing maintenance, updates, and cybersecurity measures add to the total cost of ownership. Companies must carefully assess ROI to justify AI investments.

Knowledge Gap & Expertise Shortage: AI requires specialized knowledge in data science, machine learning, and supply chain dynamics. Many companies lack in-house expertise, making adoption difficult without external partnerships. Training existing staff or hiring AI talent is both time-consuming and expensive, slowing down implementation. Collaboration with AI vendors and consultants can help bridge the knowledge gap, but it introduces dependency risks.

Integration with Legacy Systems: Many pharma supply chains rely on outdated systems that were not designed for AI-driven automation. Retrofitting AI into these existing structures is complex and expensive. Poor interoperability between legacy systems and AI-driven platforms can lead to inefficiencies and data silos. Companies must often invest in middleware or entirely new digital infrastructures, further escalating costs.

Regulatory & Compliance Hurdles: The pharmaceutical industry is highly regulated, and AI applications must comply with strict guidelines. Ensuring that AI-driven supply chain solutions meet regulatory requirements adds another layer of complexity. AI models must be transparent and explainable to meet compliance standards, which can be challenging given the ‘black-box’ nature of some algorithms. Continuous monitoring and validation are necessary to avoid legal and operational risks.

Data Availability & Quality Issues: AI thrives on high-quality, structured data. However, pharmaceutical supply chains involve multiple stakeholders, and data is often fragmented, inconsistent, or incomplete, limiting AI’s effectiveness. Ensuring data accuracy requires strong governance policies, standardized formats, and robust security measures. Poor data integration across suppliers, manufacturers, and distributors can lead to inefficiencies and incorrect AI-driven predictions.

The Future of AI in Pharmaceutical Supply Chains

As AI technology continues to evolve, its role in pharmaceutical supply chains will become even more pivotal. Future advancements may include:

AI-driven Autonomous Supply Chain Management: AI-driven autonomous systems will enable self-optimizing logistics and real-time decision-making, reducing the need for manual oversight. Machine learning algorithms will adapt to dynamic changes in supply and demand, ensuring optimal efficiency. These systems could also integrate with other AI technologies to automatically adjust production and delivery schedules based on predictive analytics.

Advanced Digital Twins: Advanced digital twins will create virtual simulations of supply chain processes, allowing companies to test strategies before implementing them in real-world environments. These virtual replicas will provide real-time insights into supply chain operations, improving risk management and reducing downtime. Additionally, digital twins will enable pharmaceutical companies to explore “what-if” scenarios, ensuring more informed decision-making and faster response times.

Hyper-Personalized Supply Chains: AI will enable hyper-personalized supply chains that predict and fulfill patient-specific medication needs more efficiently. By analyzing individual patient data, AI systems will optimize inventory and distribution based on localized demand and patient conditions. This level of personalization could lead to quicker delivery times, better medication adherence, and a more targeted approach to healthcare delivery.

Conclusion

AI is revolutionizing the pharmaceutical supply chain by improving efficiency, enhancing visibility, mitigating risks, and ensuring compliance. By automating processes and enabling real-time decision-making, AI reshapes operations from production to distribution. While challenges such as data integration and cybersecurity risks remain, the benefits far outweigh these obstacles, making AI adoption crucial for staying competitive. As AI technology evolves, it will continue driving innovation, resilience, and better healthcare outcomes. Embracing AI will also enable pharmaceutical companies to meet the demand for personalized medicine and improve the delivery of critical treatments. Contact Omega today to explore how our AI solutions can optimize your supply chain and ensure long-term success.

- https://pharmaphorum.com/rd/reducing-drug-shortages-power-ai-pharma-supply-chain-management#:~:text=AI%20offers%20a%20powerful%20toolset,resilient%20and%20sustainable%20supply%20chains.

- https://syrencloud.com/insights/role-of-ai-in-pharmaceutical-supply-chain-optimization/

- https://emerj.com/ai-pharmaceutical-supply-chains-manufacturing-laks-pernenkil-deloitte/

- https://www.sciencedirect.com/science/article/pii/S0166361524000605

- https://www.modality-solutions.com/how-artificial-intelligence-is-improving-the-pharma-supply-chain/

Subscribe

Select topics and stay current with our latest insights

- Functions