- Industries

Industries

- Functions

Functions

- Insights

Insights

- Careers

Careers

- About Us

- Technology

- By Omega Team

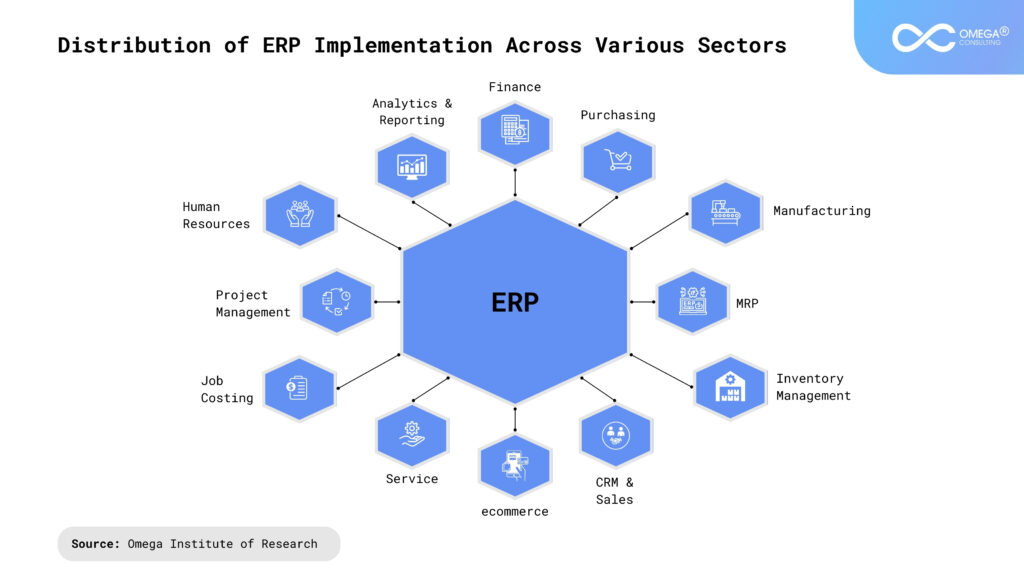

Enterprise Resource Planning (ERP) systems have become integral to the operations of businesses across industries. These systems integrate various business processes, from finance and human resources to supply chain management and customer relationship management, into a single unified system. The benefits of ERP implementation can be substantial, including improved efficiency, real-time data access, enhanced decision-making, and streamlined business processes. However, the road to successful ERP implementation is fraught with challenges, and many organizations fall victim to common pitfalls that can derail the project and diminish the expected return on investment (ROI).

In this comprehensive article, we will explore the most common mistakes organizations make during ERP implementation. By understanding these mistakes and learning how to avoid them, businesses can increase their chances of a successful ERP deployment and maximize the value of their investment.

Lack of Clear Objectives and Requirements

One of the most significant mistakes in ERP implementation is the failure to establish clear objectives and requirements from the outset. Organizations often rush into the ERP selection process without thoroughly understanding their business needs, leading to the selection of a system that may not fully align with their goals.

Undefined Business Goals

Without clear business goals, the ERP implementation can become directionless. It’s essential to define what the organization aims to achieve with the ERP system—whether it’s improving process efficiency, reducing costs, enhancing data accuracy, or enabling better decision-making. These goals should be specific, measurable, achievable, relevant, and time-bound (SMART).

Inadequate Requirements Gathering

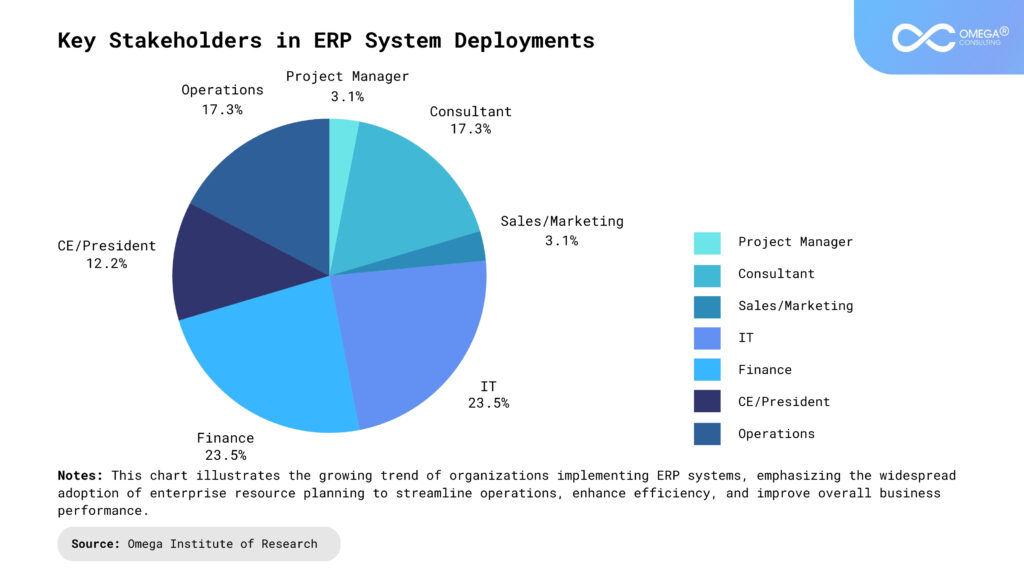

A thorough requirements-gathering process is crucial for selecting the right ERP system. Organizations often make the mistake of involving only a limited group of stakeholders in this process, leading to incomplete or inaccurate requirements. It’s essential to involve representatives from all departments that will use the ERP system to ensure that their needs are considered.

Insufficient Executive Support and Involvement

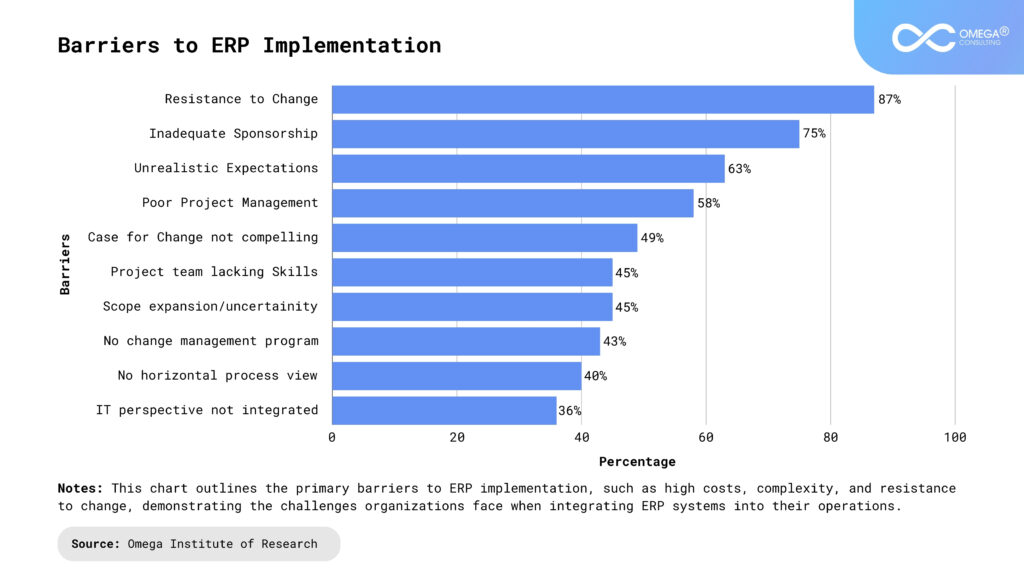

Executive support is critical for the success of an ERP implementation. Without strong backing from top management, the project may lack the necessary resources, authority, and commitment to succeed.

Lack of Executive Sponsorship

An ERP implementation is a significant undertaking that requires substantial investment and organizational change. Without an executive sponsor who champions the project and provides the necessary resources, the project may struggle to gain traction and face resistance from within the organization.

Limited Involvement of Leadership

Executives must be actively involved in the ERP implementation, not just in the planning phase but throughout the entire process. Their involvement helps ensure that the project stays aligned with the organization’s strategic goals and that any issues are promptly addressed.

Inadequate Change Management

Change management is often underestimated during ERP implementation. The introduction of a new ERP system can bring about significant changes to business processes, workflows, and job roles. Without effective change management, these changes can lead to resistance, confusion, and ultimately, project failure.

Resistance to Change

Employees may resist the new ERP system, especially if they are comfortable with existing processes or fear that the new system will make their jobs more challenging. It’s essential to communicate the benefits of the ERP system and provide training to help employees adapt to the new environment.

Poor Communication

A lack of communication can create uncertainty and anxiety among employees. Clear, consistent communication about the goals of the ERP implementation, the changes it will bring, and how it will impact employees is essential for reducing resistance and fostering a positive attitude toward the project.

Inadequate Training and Education

ERP systems are complex and require users to have a certain level of expertise to use them effectively. Inadequate training can lead to user frustration, errors, and underutilization of the system’s capabilities.

Insufficient User Training

Organizations often underestimate the amount of training required for users to become proficient with the new ERP system. Training should be comprehensive and tailored to the specific needs of different user groups, ensuring that everyone knows how to perform their tasks within the new system.

Lack of Ongoing Education

Training should not end with the initial implementation. ERP systems evolve, and employees may need ongoing education to keep up with new features, updates, and best practices. Continuous learning opportunities can help users stay proficient and make the most of the ERP system.

Poor Project Management

Effective project management is critical for the success of an ERP implementation. Without a well-structured project plan and a skilled project manager, the implementation can quickly go off track.

Unrealistic Timelines

Setting unrealistic timelines is a common mistake in ERP implementation. Organizations often underestimate the time required to complete various phases of the project, from system selection to data migration and user training. Rushing the implementation can lead to mistakes, rework, and ultimately, project delays.

Inadequate Resource Allocation

ERP implementation requires a significant investment of resources, including time, money, and personnel. Failing to allocate sufficient resources can lead to project delays, budget overruns, and a suboptimal system that doesn’t meet the organization’s needs.

Scope Creep

Scope creep occurs when the project scope expands beyond the original plan, often due to changing requirements or a lack of clear boundaries. This can lead to increased costs, extended timelines, and a final product that doesn’t align with the organization’s needs. To prevent scope creep, it’s essential to have a clear project scope from the beginning and to manage any changes through a formal change control process.

Choosing the Wrong ERP System

Selecting the wrong ERP system can have long-lasting consequences for an organization. A system that doesn’t align with the organization’s needs, processes, or industry requirements can lead to inefficiencies, increased costs, and frustration among users.

Focusing Too Much on Cost

While cost is an important consideration, it should not be the primary factor in selecting an ERP system. A lower-cost system may not provide the functionality, scalability, or support needed to meet the organization’s long-term needs. It’s essential to evaluate ERP systems based on their ability to meet the organization’s requirements and deliver value over time.

Ignoring Industry-Specific Requirements

Some ERP systems are designed for specific industries, while others offer more generic functionality. Choosing an ERP system that doesn’t align with the organization’s industry-specific needs can result in a system that requires extensive customization or doesn’t fully support critical business processes.

Overlooking Vendor Stability and Support

The ERP vendor’s stability and support capabilities are critical factors to consider. An ERP system is a long-term investment, and the vendor should be financially stable and committed to ongoing product development and support. Poor vendor support can lead to implementation challenges, slow resolution of issues, and difficulty in adapting the system to changing business needs.

Inadequate Data Migration and Management

Data migration is one of the most complex and critical aspects of ERP implementation. Poor data management can lead to inaccurate data, operational disruptions, and a lack of trust in the new system.

Poor Data Quality

Migrating poor-quality data from legacy systems to the new ERP system can undermine the entire implementation. Inaccurate, incomplete, or outdated data can lead to errors, operational inefficiencies, and poor decision-making. It’s essential to conduct a thorough data cleansing process before migration to ensure that only high-quality data is transferred to the new system.

Incomplete Data Migration

Failing to migrate all necessary data can lead to gaps in information and disrupt business processes. It’s important to have a detailed data migration plan that includes all relevant data sources and ensures that no critical data is left behind.

Lack of Data Governance

Data governance involves establishing policies and procedures for managing data throughout its lifecycle. Without a strong data governance framework, organizations may struggle to maintain data quality, consistency, and security in the new ERP system. This can lead to ongoing data management challenges and limit the effectiveness of the ERP system.

Underestimating the Complexity of Customization

ERP systems often require some level of customization to align with the organization’s specific needs. However, underestimating the complexity of customization can lead to delays, increased costs, and a system that is difficult to maintain and upgrade.

Over-Customization

While customization can be necessary, over-customization can make the ERP system overly complex and difficult to manage. Extensive customization can also complicate future upgrades, as custom code may need to be reworked or replaced to be compatible with new versions of the ERP software. It’s important to strike a balance between customization and standardization, focusing on configuring the system to meet business needs rather than customizing it extensively.

Lack of Technical Expertise

Customization often requires specialized technical skills that may not be available in-house. Relying on external consultants for customization without adequate internal oversight can lead to a lack of knowledge transfer and increased dependency on third-party vendors. Organizations should ensure they have the necessary technical expertise, either in-house or through trusted partners, to manage customization effectively.

Failure to Plan for Post-Implementation Support

ERP implementation doesn’t end with the go-live date. Ongoing support, maintenance, and continuous improvement are essential for ensuring the long-term success of the ERP system.

Inadequate Post-Implementation Support

Many organizations underestimate the need for post-implementation support, leading to challenges in resolving issues, maintaining system performance, and adapting the system to changing business needs. It’s important to have a comprehensive post-implementation support plan that includes resources for troubleshooting, system updates, and user support.

Neglecting Continuous Improvement

An ERP system should evolve with the organization. Failing to invest in continuous improvement can result in a system that becomes outdated and less effective over time. Regular reviews of the system’s performance, user feedback, and emerging business needs.

Case Studies

Understanding common ERP implementation mistakes is essential, but examining real-world examples of these pitfalls can provide valuable insights into the challenges and lessons learned from past experiences. Below are three case studies that highlight different aspects of ERP implementation failures.

Hershey’s ERP Implementation Nightmare

Background:

In the late 1990s, Hershey, a leading American chocolate manufacturer, undertook an ambitious ERP implementation project. The company aimed to upgrade its systems to improve efficiency and better manage its supply chain.Mistakes:

- Unrealistic Timeline: Hershey attempted to implement the ERP system during its busiest season, the Halloween rush. The project was rushed, with a timeline of 30 months reduced to just 18 months.

- Insufficient Testing: Due to time constraints, the company did not adequately test the system before going live. This resulted in critical issues during the initial rollout.

Consequences:

The result was disastrous: Hershey was unable to fulfill $100 million worth of orders during the critical Halloween season, leading to a significant loss of revenue and a sharp decline in stock value. The ERP implementation became a textbook example of what can go wrong when timelines are unrealistic, and testing is inadequate.Lessons Learned:

Organizations should never rush an ERP implementation, especially during peak business periods. Thorough testing and realistic timelines are essential for a successful rollout.The U.S. Navy’s Failed ERP Project

Background:

The U.S. Navy embarked on a multi-billion-dollar ERP project to consolidate its financial, supply chain, and workforce management systems across its global operations. The goal was to improve operational efficiency and reduce costs.Mistakes:

- Scope Creep: The project suffered from significant scope creep, with additional requirements being added continually, leading to increased complexity and costs.

- Poor Change Management: The Navy struggled with change management, as the scale of the project required a massive shift in processes and culture across a highly decentralized organization.

Consequences:

After spending over $1 billion, the project was eventually scrapped, having delivered minimal benefits. The Navy’s failure to control scope and manage change effectively led to one of the most expensive ERP failures in history.Lessons Learned:

Large-scale ERP implementations must have strict scope management and robust change management strategies. Without these, projects can spiral out of control and fail to deliver value.Waste Management’s Legal Battle with SAP

Background:

Waste Management, a major U.S. waste disposal company, partnered with SAP to implement an ERP system that would streamline its operations and improve customer service.Mistakes:

- Misaligned Expectations: Waste Management claimed that SAP had oversold the capabilities of its software, leading to a misalignment between what was promised and what was delivered.

- Lack of Executive Involvement: The project lacked strong executive oversight, which resulted in poor communication and decision-making throughout the implementation.

Consequences:

The implementation failed, leading to a lawsuit where Waste Management sought $100 million in damages. The legal battle highlighted the importance of aligning expectations and maintaining strong executive involvement throughout the project.Lessons Learned:

Clear communication and alignment between the organization and the ERP vendor are crucial for project success. Executives must be actively involved to ensure the project stays on track and issues are addressed promptly.Future Trends in ERP Implementation

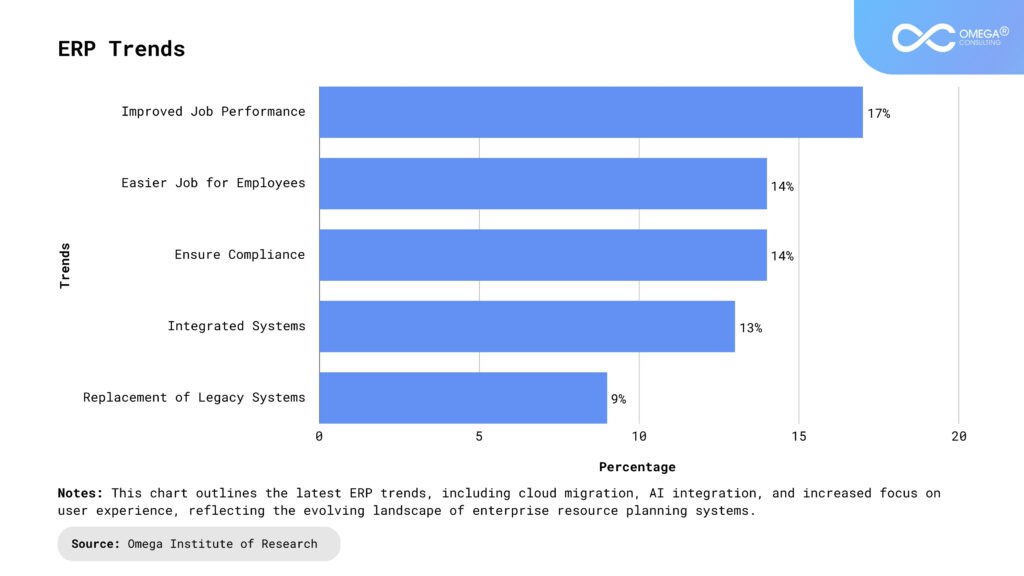

As technology and business environments continue to evolve, ERP systems are also undergoing significant transformations. Understanding future trends can help organizations better prepare for ERP implementation and avoid common pitfalls.

Cloud-Based ERP Systems

The shift towards cloud-based ERP systems is one of the most significant trends in the industry. Cloud ERP offers several advantages, including lower upfront costs, scalability, and easier access to updates and new features. As more organizations move to the cloud, on-premise ERP systems may become less common.

Implications:

- Organizations must carefully consider data security and compliance when moving to cloud-based ERP systems.

- The flexibility of cloud ERP allows for more agile implementation, but it also requires a strong governance framework to manage ongoing updates and changes.

AI and Machine Learning Integration

AI and machine learning are increasingly being integrated into ERP systems to enhance decision-making, automate routine tasks, and provide predictive insights. These technologies can help organizations optimize processes, reduce errors, and improve efficiency.

Implications:

- Organizations must ensure that their data infrastructure is capable of supporting AI and machine learning capabilities.

- Training and change management will be critical as employees adapt to AI-driven processes and workflows.

Industry-Specific ERP Solutions

The demand for industry-specific ERP solutions is growing as organizations seek systems tailored to their unique needs. These solutions offer specialized functionality and features that can reduce the need for extensive customization.

Implications:

- Organizations should evaluate ERP systems based on their industry-specific requirements to ensure they select a solution that aligns with their business processes.

- Industry-specific solutions may offer faster implementation times and lower costs, but organizations must still ensure that the system can scale and adapt to future needs.

Increased Focus on User Experience (UX).

As ERP systems become more complex, there is a growing emphasis on improving the user experience. Modern ERP systems are being designed with more intuitive interfaces, mobile accessibility, and enhanced user training to reduce the learning curve and improve adoption.

Implications:

- A better user experience can lead to higher user satisfaction and more effective use of the ERP system.

- Organizations should involve end-users in the selection and design process to ensure that the system meets their needs and preferences.

Integration with IoT and Big Data

The integration of ERP systems with the Internet of Things (IoT) and big data analytics is enabling organizations to gain real-time insights into their operations. This integration allows for more accurate forecasting, better inventory management, and improved asset tracking.

Implications:

- Organizations must invest in the necessary infrastructure and tools to support IoT and big data integration with their ERP systems.

- The ability to harness real-time data can provide a competitive advantage, but it also requires robust data governance and security measures.

Focus on Sustainability and ESG Compliance

Sustainability and environmental, social, and governance (ESG) considerations are becoming increasingly important for organizations. ERP systems are being enhanced with features that help organizations track and report on their sustainability and ESG metrics.

Implications:

- Organizations should look for ERP systems that support their sustainability goals and provide the necessary tools for ESG compliance.

- The ability to track and report on sustainability metrics can enhance an organization’s reputation and meet regulatory requirements.

Conclusion

ERP implementation is a complex and challenging process that requires careful planning, strong leadership, and effective execution. The common mistakes outlined in this article—ranging from lack of clear objectives and insufficient executive support to inadequate data management and poor project management—highlight the areas where organizations often falter. By learning from these mistakes and applying best practices, businesses can increase their chances of a successful ERP implementation and realize the full benefits of their investment.

The case studies presented offer valuable lessons from real-world experiences, emphasizing the importance of realistic timelines, strong change management, and alignment between business needs and system capabilities. As the ERP landscape continues to evolve, staying informed about future trends—such as cloud-based systems, AI integration, and a focus on user experience—will be crucial for organizations looking to remain competitive and agile.

In conclusion, successful ERP implementation requires a holistic approach that considers not only the technical aspects of the system but also the organizational culture, processes, and people involved. By avoiding common pitfalls and embracing emerging trends, organizations can leverage ERP systems to drive efficiency, innovation, and long-term growth.

- https://www.deskera.com/blog/erp-implementation-mistakes/

- https://flextecs.com/resources/enterprise-resource-planning-erp-errors

- https://www.aptean.com/en-US/insights/blog/avoid-erp-implementation-pitfalls

- https://eventura.com/erp/common-erp-implementation-mistakes/

- https://www.withum.com/resources/erp-implementation-failure-8-mistakes-to-avoid/

- https://www.apty.io/blog/erp-implementation/

Subscribe

Select topics and stay current with our latest insights

- Functions