- Industries

Industries

- Functions

Functions

- Insights

Insights

- Careers

Careers

- About Us

- Technology

- By Omega Team

Microchip is a general term of semiconductor component products, the carrier of integrated circuit, separated by a wafer. It is generally an important part of computer or other electronic equipment. The fabrication of microchips is to integrate electronic components such as resistors and capacitors and the circuits composed by them into a small silicon particle. Microchips are very sophisticated instruments, measured in nanometers. A typical Intel Core CPU has a core about the size of a human fingernail but contains billions or even tens of billions of transistors. Chips are used in many of our daily lives, including work, transportation, medicine, and entertainment. This small but extremely important device is making people’s lives smarter and smarter.

The first experience of microchip implant was conducted in 1998 with a radio-frequency identification (RFID) implant by British scientist Kevin Warwick. This technology was approved to store medical information in 2004 by US Food and Drug Administration (FDA). In 2018, the medical implant tags offering continuous monitoring was also approved by FDA to monitor blood glucose levels in diabetic patients. Although microchip technology implant is still not widely accepted in the United States, it already has some legal backings, and it is expected to lead to a breakthrough in the development of the technology of drug treatments.

New Drug Delivery Technologies and Microchips

As drug therapies become increasingly complex and effective in treating disease, their effectiveness can be dramatically affected by how the drug is delivered. Traditional routes of administration, such as oral capsules or intravenous infusion, encounter problems in maintaining drug concentrations within the therapeutic window, wherein the drug is above a threshold for efficacy but not toxic to the patient. Much previous work in drug delivery focused on achieving sustained drug release rates over time, while a more recent trend is to make devices that allow the release rate to be varied over time.

Advances in microfabrication technology have made an entirely new type of drug delivery device possible. Proof-of-principle experiments have shown that silicon microchips can store and release multiple chemicals on demand. Future integration of active control electronics, such as microprocessors, remote control units, or biosensors, could lead to the development of a ‘pharmacy on a chip’, ‘smart’ microchip implants, or tablets that release drugs into the body automatically when needed.

Fabrication and Drug Release Mechanism

Microchips for drug delivery are fabricated using the same well-developed technology as used for microelectronic integrated circuits and microelectromechanical systems. To allow for accurate control of surface microarchitecture, microchips are created using repetitive thin-film deposition, photolithography, and etching.

Figure 1: Process

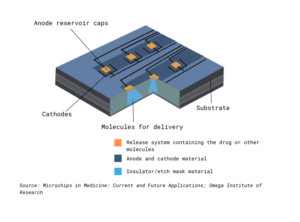

The microchips consist of hundreds of reservoirs filled with up to 1 mL of drugs in an aseptic solid, liquid, or gel filing. The multi-reservoir microchips are hermetically sealed to avoid degradation and subsequently covered by an anode membrane which can be ablated electrothermally to release the reservoir contents.

Figure 2: Diagram of Chip

Microreservoir release is achieved by applying a voltage between the thin, metallic anode membrane and a cathode to electrochemically dissolve the reservoir cover. This electrical potential can be activated wirelessly, external to the body, or secondary to metabolic changes in the host. The control circuitry can be integrated into the microchips. This circuitry includes a timer, demultiplexer, microprocessor, and input source (e.g., biosensor). Such controlled drug delivery can release drugs over months, on a preset or as-needed schedule.

The current microchips in Drug Delivery under Development

MIT has taken the lead in developing this drug delivery technology. Dr. Robert Langer had received numerous awards for innovation in the medical field. One of Langer’s students, John Santini, did his doctoral thesis on developing a drug delivery device, an implanted chip. After years of research and animal testing, devices consisting of arrays of microchips can store hundreds of therapeutic doses of drugs. In clinics, doctors can easily implant patients with sealed, individually packaged drug delivery devices that can store hundreds of doses and last for months or even years. In addition, each array of chips contains several milligrams of a specific drug, which can be automatically and accurately delivered according to a predetermined schedule or in real-time through an application controlled by the patient or caregiver.

Langer and another professor, along with John Santini, founded Microchips Biotech, an American company that mainly uses implanted Microchips to inject drugs into patients. The company’s microchips contain “hundreds of pinhead-sized repositories of treatment plans” that are released when an electric current is applied. The company says its chips can be used to treat diabetes, cancer, multiple sclerosis, and osteoporosis, and will last in the body for 16 years.

This company previously received funding from the Bill and Melinda Gates Foundation to develop another important product, the contraceptive microchip. Ovaprene is a novel, hormone-free monthly intravaginal contraceptive candidate designed to provide contraception over multiple weeks by releasing a locally acting agent which impedes sperm motility. This technology is believed to have a great potential to be widely promoted in developing countries, offering women a safe and convenient contraceptive method.

Advantages:

Simplicity of release mechanism

The liberation of chemicals from the microchip is instigated by fragmentation of the membrane. The membrane is shattered by the application of an electric potential, which cause the membrane to dissolve by simple electrochemical reaction. The absence of moving parts possibly enhances device reliability by lowering the possibility of mechanical breakdown.

Accuracy of dose

The amount of the drug administered from a microchip filled by a printing technique can be firmly regulated and accidental overdose can also be escaped because release from active devices can only occur when an electric potential will be applied to an anode.

Improve shelf-life

The membrane layering the packed reservoir of a microchip will prevent the diffusion of water into these reservoirs. Thus, the stability of protein drugs can be enhanced firstly by isolating the drug from the outside environment (hermetically sealed) and secondly by storing the microchip in its most stable form (solid, liquid, or gel).

Potential for local delivery

The microchip device can be made infinitesimal to bring about the local chemical delivery possible. The principal benefit of local drug delivery is that high concentrations of the drug can be attained at the site where it is required while keeping the systemic concentrations low.

Future Outlook

The widespread application of microchip technology has the potential to be transformative to the modern healthcare system. Billions of dollars’ worth of unnecessary expenses will be avoided, and the quality of life of patients will increase. Therapeutic processes will be changed and the quality of life for patient populations will increase.

While human studies involving microchips have been limited to treating a few specific diseases, advancements will allow the expansion of this technology into a larger range of therapeutic areas. Microchip delivery systems will aid in the treatments for diseases that classically include a lower rate of compliance (mental disorders, some cancer therapeutics, long-term antibiotics, etc.) or potential for abuse.

While still in the development stages, microchip technology will have a large impact on the diabetes treatment landscape. Current diabetes treatments are largely limited by delivery methods. Oral therapies offer a low bioavailability and relatively delayed impact. While liquid insulin (in the form of pumps or syringes) has a high bioavailability and fast entrance into the systemic circulation, patients are often deterred from considering it as a therapy option because of the need for self-injection. Furthermore, error in treatment occurs frequently with both methods of insulin therapy when patients give themselves the wrong dosage or forget to test their blood. Microchip technology will become a blockbuster product in the field of diabetes drug treatment and save thousands of lives. If a clinical trial is under way, based on the existing statistics, it can be extrapolated that a raw sales peak will be reached in 2035.

Microfabrication: The process of fabricating miniature structures of micrometer scales and smaller

Microprocessors: An integrated circuit that contains all the functions of a central processing unit of a computer.

Microelectromechanical(MEMS): Mechanical parts and electronic circuits combined to form miniature devices, typically on a semiconductor chip, with dimensions from tens of micrometres to a few hundred micrometres (millionths of a metre).

Microarchitecture: The way a given instruction set architecture is implemented in a particular processor

Photolithography: A process used in microfabrication to pattern parts on a thin film or the bulk of a substrate. It uses light to transfer a geometric pattern from a photomask to a photosensitive chemical photoresist on the substrate.

Etching: To chemically remove layers from the surface of a wafer during manufacturing.

Multi-reservoir: Water diffuses through membrane into the tablet reservoirs and drug is released as the reservoirs open.

Electrothermally: Heat derived from electricity.

Demultiplexer: a device that takes a single input line and routes it to one of several digital output lines

Intravaginal: Medications are applied inside the vagina

Subscribe

Select topics and stay current with our latest insights

- Functions