- Industries

Industries

- Functions

Functions

- Insights

Insights

- Careers

Careers

- About Us

- Information Technology

- By Omega Team

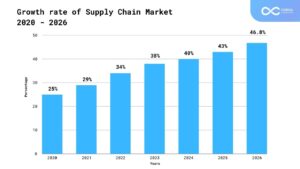

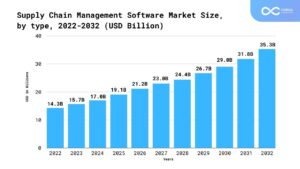

In the dynamic realm of technology-driven business strategies, Chief Information Officers (CIOs) and Chief Technology Officers (CTOs) stand as vanguards, guiding organizations toward the realms of digital transformation and operational excellence. Serving as the digital backbone of modern enterprises, these executives hold a pivotal role in harnessing technology to optimize diverse facets of business operations. A critical domain requiring their astute focus is Supply Chain Optimization – a strategic imperative transcending traditional logistics and procurement. This article will thoroughly explore the reasons why Supply Chain Optimization holds paramount importance for CIOs and CTOs, elucidating how it can profoundly influence the overall success of their organizations.

Understanding Supply Chain Optimization

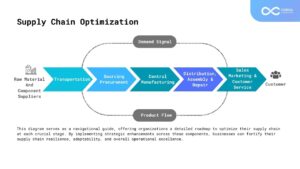

At its core, supply chain optimization is the systematic refinement of processes to achieve the highest levels of efficiency, cost-effectiveness, and responsiveness. This involves the seamless integration of people, processes, technology, and resources to meet customer demands while minimizing waste and costs. This multidimensional approach requires a deep understanding of various components, each playing a crucial role in the overall success of the supply chain.

Demand Forecasting and Planning

Accurate demand forecasting serves as the foundation for supply chain optimization. Leveraging advanced analytics, machine learning algorithms, and historical data, organizations can predict customer demand with greater precision. By understanding market trends and consumer behavior, businesses can align production schedules and inventory levels more closely with actual demand, minimizing the risk of overstock or stockouts.

Inventory Management

Effective inventory management is a cornerstone of supply chain optimization. Balancing the need to maintain sufficient stock levels with the imperative to reduce carrying costs requires sophisticated strategies. Adopting just-in-time (JIT) inventory practices, implementing safety stock calculations, and utilizing state-of-the-art inventory tracking systems enable organizations to optimize stock levels, reduce holding costs, and enhance overall supply chain agility.

Supplier Relationship Management (SRM)

The collaboration between businesses and their suppliers is a pivotal aspect of supply chain optimization. Developing strong, mutually beneficial relationships with suppliers fosters transparency, improves communication, and enhances overall supply chain resilience. Through shared information and joint planning, organizations can mitigate risks, negotiate better terms, and ensure a consistent supply of high-quality materials.

Technology Integration

The digital transformation of supply chains is an ongoing process that involves the integration of advanced technologies. Artificial intelligence (AI), the Internet of Things (IoT), and blockchain are among the technologies reshaping the supply chain landscape. AI-powered predictive analytics can optimize decision-making, IoT devices enable real-time tracking and monitoring, and blockchain ensures transparent and secure transactions throughout the supply chain.

Transportation Management

Efficient transportation logistics are vital for reducing lead times and costs associated with moving goods. Route optimization, load consolidation, and the adoption of advanced tracking systems contribute to streamlined transportation processes. This not only lowers costs but also enhances the overall reliability and timeliness of deliveries.

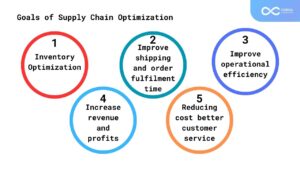

Benefits of Supply Chain Optimization

Cost Reduction

Supply chain optimization offers tangible cost-reduction benefits. By identifying and eliminating inefficiencies, organizations can reduce operational costs associated with inventory holding, transportation, and production processes. This, in turn, contributes to improved profit margins and a more competitive market position.

Improved Customer Satisfaction

Customer satisfaction is intricately linked to the ability to meet and exceed customer expectations. A well-optimized supply chain ensures that products are available when and where customers need them, leading to shorter lead times, improved delivery reliability, and ultimately higher levels of customer satisfaction.

Enhanced Agility and Flexibility

The dynamic nature of modern business requires organizations to be agile and responsive to changing market conditions. Supply chain optimization provides the flexibility to adapt to fluctuations in demand, respond swiftly to market trends, and navigate disruptions effectively. This adaptability enhances the overall resilience of the organization.

Risk Mitigation

An optimized supply chain is better equipped to identify, assess, and mitigate risks. Whether arising from natural disasters, geopolitical events, or other unforeseen circumstances, a robust supply chain management strategy enables organizations to proactively manage and navigate through disruptions, ensuring business continuity.

Supply Chain Management

Supply Chain Management (SCM) stands as a multifaceted and integral discipline, playing a pivotal role in orchestrating the seamless flow of products and services from their conceptualization to the hands of the end consumer. This intricate process involves a series of strategic, operational, and technological considerations that collectively optimize the efficiency, responsiveness, and sustainability of the supply chain ecosystem.

Strategic Planning:

- SCM commences with meticulous strategic planning, incorporating forecasting and market analysis to align production and distribution with anticipated demand.

- Decisions made during this phase set the foundation for the entire supply chain process, influencing subsequent activities.

Sourcing and Procurement:

- This phase revolves around acquiring materials, components, and services essential for production.

- The establishment of robust supplier relationships, meticulous evaluation of reliability, and effective negotiation of favorable terms are critical to ensuring a resilient supply chain.

Production and Manufacturing:

- Emphasis is placed on the efficient and sustainable transformation of raw materials into finished goods.

- Rigorous quality control measures are implemented to guarantee that products meet or exceed established standards.

Distribution and Logistics:

- Management of the movement of goods from production facilities to distribution centers and, ultimately, to end consumers.

- Optimization of logistics, transportation, and warehouse processes minimizes lead times, reduces costs, and enhances overall supply chain performance.

Inventory Management:

- Involves maintaining optimal inventory levels to balance supply and demand effectively.

- The goal is to prevent stockouts, minimize holding costs, and foster overall agility within the supply chain.

Information Systems and Technology:

- Leveraging advanced technologies such as artificial intelligence, real-time tracking, and seamless communication to enhance visibility and collaboration.

- Information systems play a pivotal role in supporting data-driven decision-making across the entire supply chain network.

Challenges in Supply Chain Optimization

Despite its undeniable benefits, supply chain optimization is not without its challenges. Some of the common obstacles include:

Data Management and Integration

Effective supply chain optimization relies heavily on data. However, many organizations struggle with integrating data from various sources and platforms. Achieving a seamless flow of information across the entire supply chain requires robust data management systems and interoperable technologies.

Talent and Skill Shortages

The implementation and management of advanced technologies demand a skilled workforce. Organizations may face challenges in recruiting and retaining professionals with expertise in data analytics, AI, and other emerging technologies critical to supply chain optimization.

Resistance to Change

Implementing supply chain optimization initiatives often requires a cultural shift within organizations. Resistance to change from employees, stakeholders, or established processes can impede progress. Effective change management strategies are essential to overcoming this challenge.

Future Trends in Supply Chain

Optimization: As technology continues to evolve, several trends are shaping the future of supply chain optimization:

Sustainability

There is an increasing emphasis on sustainability within supply chain operations. Organizations are integrating environmentally friendly practices, such as green logistics, circular supply chains, and eco-friendly packaging, to align with growing consumer expectations for responsible and sustainable business practices.

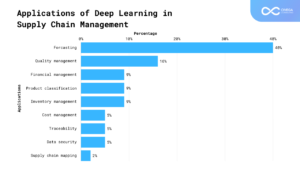

Artificial Intelligence and Machine Learning

AI and machine learning will play an even more significant role in supply chain optimization. Predictive analytics, demand forecasting, and autonomous decision-making processes powered by AI will enhance efficiency and responsiveness.

Blockchain Technology

The use of blockchain technology is gaining traction for its ability to provide transparent, secure, and traceable transactions throughout the supply chain. This helps mitigate risks related to fraud, counterfeiting, and information discrepancies.

3D Printing and Additive Manufacturing

Advancements in 3D printing and additive manufacturing technologies are revolutionizing traditional supply chain models. The ability to produce customized, on-demand products locally reduces the reliance on centralized manufacturing and global distribution networks.

Conclusion

In the era of hyper-globalization and technological acceleration, supply chain optimization has become a strategic imperative for businesses aiming to thrive in a competitive landscape. The multifaceted approach of optimizing demand forecasting, inventory management, supplier relationships, technology integration, and transportation logistics enables organizations to achieve operational excellence, reduce costs, and enhance customer satisfaction. As the business environment continues to evolve, those who embrace and innovate within the realm of supply chain optimization will undoubtedly position themselves as leaders in their respective industries.

Subscribe

Select topics and stay current with our latest insights

- Functions